Gothenburg-headquartered Cellink has gone from a start-up to one of the world’s leading 3D bioprinting firms in just four years; firmly positioning Sweden at the forefront of this potentially revolutionary new technology.

In the coming decade we would like to continue to push the boundaries of 3D bioprinting until it becomes an established technology in the medical field

Hector Martinez, Cellink

Humble Beginnings

In 2015, realising that it was impossible to purchase bioink for 3D bioprinting, Erik Gatenholm and Hector Martinez set out to create a universal bioink that could be used by anyone working in bioprinting.

Having created a product and formed Cellink, the company’s rise under Gatenholm – now CEO – and Martinez – now CTO – since that point has been staggering. With the first sale of their ink coming within its first 24 hours on the market, Cellink listed on the Nasdaq First North stock exchange merely 10 months later after a 1070 percent oversubscribed IPO.

Shares have since risen in value by 400 percent and the firm’s market capitalization stands at around USD 255 million as of May 2019. Its founders have also been catapulted into the spotlight, with Gatenholm making the 2018 Forbes ’30 Under 30’ list of influential young businesspeople.

Tech Specs

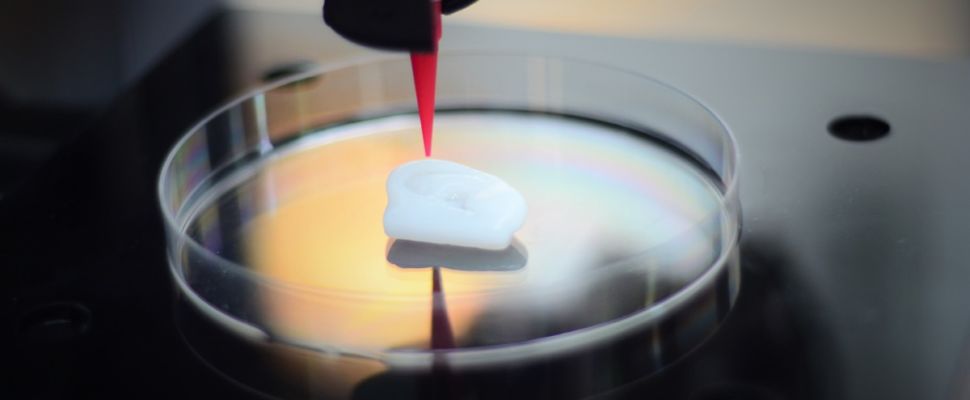

Cellink’s value proposition is a combination of bioink and bioprinters. Bioink is a gel that can be extruded through a printing nozzle and mimics the suspension lying between cells, known as the extracellular matrix.

As Alberto Iglesias Fraga of Business Insider notes, “Cellink’s gels are unique, in that they have very specific qualities: they’re viscose, gelatinous, can be built into networks, can be manufactured in next to no time, and have an incredible level of tensile strength.”

Using its own printers, which are extraordinarily accurate and extremely fast, Cellink can create skin, liver cells and various other organs. An entire ear can be built in just 20 minutes. On the market for USD 39,000, Cellink’s Bio X printer is “up to 10 times cheaper than that of our direct competitor,” states the company’s chief scientific officer, Itedale Namro Redwan, potentially expanding access to 3D bioprinting technology across the globe.

Cancer Research

In addition to printing body parts to be implanted on patients, Cellink’s technology also allows for the reproduction of specific cancerous tumours. By printing out these tumours, doctors can experiment with treatment options in vitro without endangering the life of the patient.

Gatenholm states that the technology gives doctors the chance to test, “which treatment could specifically work on that patient.”

Stakeholders across the healthcare continuum are starting to take note, with Cellink having already received a EUR 2.5 (USD 2.8) million grant from the European Union to develop these tumour modelling printers.

Looking Forward

Cellink’s founders have grand ambitions for the future as pioneers of 3D bioprinting technology. “What we’re doing here is developing the technology which allows scientists and researchers to create human organs and tissues using a biological ink, modified 3D printers and human cells,” said Gatenholm in an interview with Digital Trends. “What we do at Cellink is to provide this entire package of components to customers and users worldwide so that they can get started as easily as possible.”

Martinez adds, “In the coming decade we would like to continue to push the boundaries of 3D bioprinting until it becomes an established technology in the medical field. We have the vision of becoming the first and number one provider of bioprinters, bioinks, software and technical know-how for the next generation of medical device manufacturers.”